The Split Frame Clamshell CNC Crossbar brings full CNC precision to field machining without changing the way your crew sets up. Built to integrate directly with TAG’s TSFC-series split frames, it turns a single setup into a complete machining workflow: perform an initial cut, then execute the programmed prep, or go straight to CNC preparation when time is tight. Servo-driven control and true two-axis interpolation deliver repeatable geometry and weld-ready finishes across the toughest materials.

-

CNC accuracy on a split frame: Single-point, fully programmable CNC crossbar for consistent profiles and surface finishes on TSFC-series clamshells.

-

One-setup efficiency: Mount once to rough cut and complete CNC preparation without repositioning, speeding turnarounds and reducing risk.

-

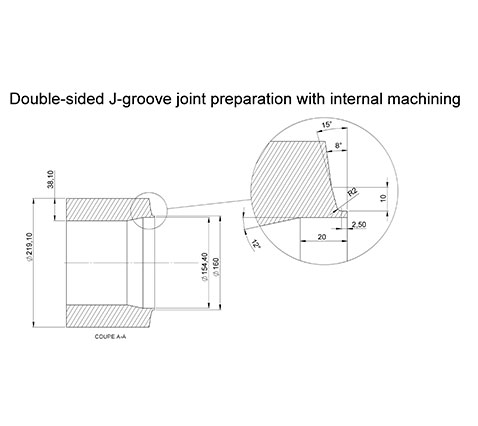

True X/Z interpolation: Two brushless axis drives precisely control tool path and bevel geometry for V/J, compound, and custom forms.

-

Wide process coverage: External V/J-bevel, internal bevel, compound bevel, counter-boring, weld removal, flange facing and preparation (flat face, raised face, RTJ groove, male & female), NORSOK compact flange machining, OD turning, radius prep, and heat-exchanger seal-face machining.

-

User-controlled programming: 7″ wired touchscreen remote pad with intuitive, license-free software; set rotation speed, feed, depth of cut, and trajectories on the fly.

-

Stable, chatter-resistant cuts: Servo-controlled rotation and robust crossbar architecture improve finish quality and reduce rework.

-

Power you can trust: Three-phase 380–480V electrical controller with servo motor provides smooth torque and repeatable speed control.

-

Machines the hard stuff: Proven on all steels, exotic alloys, titanium, and other hard materials while protecting tool life.

-

Fast field integration: Drop-in compatibility with TAG’s standard TSFC-series frames keeps crews productive with familiar fixtures.

Put simply, the Split Frame Clamshell CNC Crossbar combines the portability of a split frame with the precision of a CNC, so you can deliver code-driven accuracy, faster turnarounds, and consistent weld-ready results on any site.