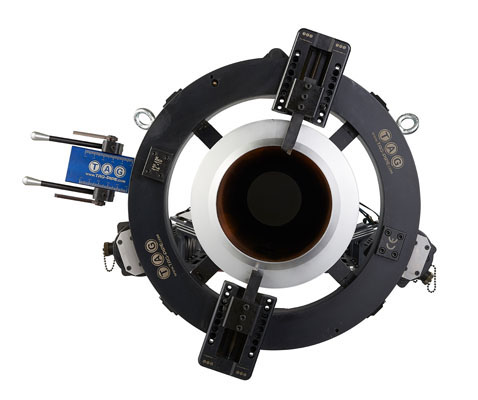

The TAG Split Frame Clamshell Cold Cutting and bevelling Machine is a versatile, portable lathe designed for precise pipe cutting, bevelling, facing, and counter-boring on pipes from 1″ to 48″ outer diameter. Built to handle a variety of materials, including steel and exotic alloys, this pipe cutting machine features a lightweight aluminum body with a durable steel inner ring gear mounted on solid bearings for enhanced stability. Wide, hardened clamping feet with easy-to-read measurement marks enable fast and repeatable setups, even on out-of-round pipes. With pneumatic, electric, hydraulic, and servo electric power options, the machine adapts seamlessly to diverse job requirements. Adjustable bearings, accessible maintenance points, and customizable TAG transmission tool slides make this pipe cutting and pipe bevelling machine a flexible, efficient solution for on-site or workshop applications across industries.

Split Frame 1" to 48" Clamshell Machine

RANGE: 1" - 48" o/d / 25.4 - 1,220 mm o/d

Mobile Nav

| Description | TSFC3 | TSFC6 | TSFC8 | TSFC12 | TSFC16 | TSFC18 | TSFC20 | TSFC24 | TSFC30 | TSFC36 | TSFC42 | TSFC48 |

| Locking Range (Inch) | 1 – 3″ | 1 – 6″ | 2 – 8″ | 6 – 12″ | 10 – 16″ | 12 – 18″ | 14 – 20″ | 18 – 24″ | 24 – 30″ | 30 – 36″ | 36 – 42″ | 42 – 48″ |

| Locking Range (MM) | 33.4 – 88.9 mm | 33.4 – 168.3 mm | 60.3 – 219.1 mm | 168.3 – 323.9 mm | 273.0 – 406.4 mm | 323.9 – 457.0 mm | 355.6 – 508.0 mm | 457.0 – 610.0 mm | 609.6 – 762 mm | 762 -914.4 mm | 914.4 – 1,066.8 mm | 1,066.8 – 1,219.2 mm |

| Ring Only Weight | 12 kg | 23 kg | 32 kg | 46 kg | 53 kg | 58 kg | 62 kg | 76 kg | 183 kg | 204 kg | 242 kg | 323 kg |

| Toolbox Stroke | 30 mm / 1.18″ | 60 mm / 2.36″ | 60 mm / 2.36″ | 90 mm / 3.54″ | 90 mm / 3.54″ | 90 mm / 3.54″ | 90 mm / 3.54″ | 90 mm / 3.54″ | 90 mm / 3.54″ | 90 mm / 3.54″ | 90 mm / 3.54″ | 90 mm / 3.54″ |

| Motor Mount Positions | 1 qty | 1 qty | 1 qty | 1 qty | 2 qty | 2 qty | 2 qty | 2 qty | 2 qty | 2 qty | 4 qty | 4 qty |

| Striker Mount Positions | 1 qty | 1 qty | 1 qty | 2 qty | 3 qty | 3 qty | 3 qty | 3 qty | 3 qty | 4 qty | 4 qty | 5 qty |

| Bearing size | S | S | S | S | S | S | S | S | L | L | L | L |

| Spline Drive Size | 16 mm / 0.63″ | 16 mm / 0.63″ | 16 mm / 0.63″ | 16 mm / 0.63″ | 16 mm / 0.63″ | 16 mm / 0.63″ | 16 mm / 0.63″ | 16 mm / 0.63″ | 25 mm / 0.98″ | 25 mm / 0.98″ | 25 mm / 0.98″ | 25 mm / 0.98″ |

| Pneumatic Idle Speed | 5 – 44 rpm | 5 – 36 rpm | 5 – 28 rpm | 5 – 21 rpm | 5 – 18 rpm | 5 – 17 rpm | 5 – 16 rpm | 5 – 15 rpm | 1 – 8 rpm | 1 – 8 rpm | 1 – 7 rpm | 1 – 6 rpm |

| Electric Idle Speed | 5 – 40 rpm | 5 – 20 rpm | 5 – 16 rpm | 5 – 12 rpm | n/a | n/a | n/a | n/a | n/a | n/a | n/a | n/a |

| Servo Electric Idle Speed | n/a | 1 – 45 rpm | 1 – 36 rpm | 1 – 27 rpm | 1 – 23 rpm | 1 – 21 rpm | 1 – 19 rpm | 1 – 18 rpm | 1 – 9 rpm | 1 – 9 rpm | 1 – 8 rpm | 1 – 7 rpm |

| Hydraulic Idle Speed | n/a | 5 – 30 rpm | 5 – 28 rpm | 5 – 25 rpm | 5 – 20 rpm | 5 – 19 rpm | 5 – 17 rpm | 5 – 16 rpm | 1 – 8 rpm | 1 – 8 rpm | 1 – 8 rpm | 1 – 8 rpm |

| Pneumatic Motor Power | 1.85 hp | 1.85 hp | 1.85 hp | 1.85 hp | 1.85 hp | 1.85 hp | 1.85 hp | 1.85 hp | 3.5 hp | 3.5 hp | 3.5 hp | 3.5 hp |

| Double Pneumatic Motor(s) Power | n/a | n/a | n/a | n/a | 3.7 hp | 3.7 hp | 3.7 hp | 3.7 hp | 7 hp | 7 hp | 7 hp | 7 hp |

| Electric Motor Power | 1900 watt | 1900 watt | 1900 watt | 1900 watt | n/a | n/a | n/a | n/a | n/a | n/a | n/a | n/a |

| Single Servo Electric Motor Power | n/a | 1.5 Kw | 1.5 Kw | 1.5 Kw | 1.5 Kw | 1.5 Kw | 1.5 Kw | 1.5 Kw | 1.5 Kw | 1.5 Kw | 1.5 Kw | 1.5 Kw |

| Double Servo Electric Motor(s) Power | n/a | n/a | n/a | n/a | 3 Kw | 3 Kw | 3 Kw | 3 Kw | 3 Kw | 3 Kw | 3 Kw | 3 Kw |

| Hydraulic Motor Power | n/a | 5.4 hp | 5.4 hp | 5.4 hp | 5.4 hp | 5.4 hp | 5.4 hp | 5.4 hp | 5.4 hp | 5.4 hp | 5.4 hp | 5.4 hp |

| Electric / Servo Electric Voltage | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt | 110 / 220 volt |

| Electric / Servo Electric Frequency | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz | 50 / 60 Hz |

| Air Working Pressure | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar | 90 psi / 6.5 bar |

| Air hose Connection | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 3/4″ | 3/4″ | 3/4″ | 3/4″ |

| Air Consuming Flux (Double x2) | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM | 50 cfm / 1400 LPM | 90 cfm / 2500 LPM | 90 cfm / 2500 LPM | 90 cfm / 2500 LPM | 90 cfm / 2500 LPM |

| Feed Rate per Revolution | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ | 0.2 mm / 0.008″ |

| Locking System | Modular | Modular | Modular | Modular | Modular | Modular | Modular | Modular | Telescopic | Telescopic | Telescopic | Telescopic |

The TAG Split Frame Clamshell Cold Cutting and Bevelling Machines, designed for pipe diameters ranging from 1″ to 48″ (with larger, customized sizes available upon request), are advanced portable lathes built for versatility and durability in challenging industrial settings. These pipe cutting machines are ideal for a wide range of cutting, bevelling, and machining tasks on pipes and vessels of various sizes. With a lightweight aluminum body and a robust steel inner ring gear, TAG clamshells offer smooth operation, even on out-of-round pipes. Featuring hardened clamping feet with easy-read measurement markings, the design enables rapid, accurate setups. The modular system supports various power drive options, ensuring adaptability for heavy-duty on-site work across diverse industries.

Features and Advantages

- Range of Models: Accommodates pipe diameters from 1″ (25.4 mm) to 48″ (1,220 mm) o/d, suitable for different industrial requirements.

- Multiple Power Options: Available with pneumatic, hydraulic, standard electric (110v or 220v), and NC servo electric motors, enhancing versatility across applications.

- Adjustable Heavy-Duty Bearings: Equipped with TAG’s advanced cam roller bearing system, allowing fine-tuned adjustments for optimized performance and smooth rotation.

- Quick, Accurate Setup: Adjustable clamping feet with a flush hex head and clear measurement markings allow for rapid, precise setups and adjustments.

- Enhanced Feed System: TAG’s worm and crown feeding system ensures even pressure distribution, minimizing vibration and tool wear during operation.

- Customizable Tooling: Accepts various pipe cutting tools and modular locking options to tailor the machine for specific jobs, including bevelling and counterbore tasks.

- Telescopic Jaws: Externally mounted telescopic jaws with an increased clamping foot size (55 x 115 mm) enhance stability and precision.

Easy Motor Mounting: Two-bolt motor mount system allows for quick and secure motor attachment. - Protective Storage: Supplied with a custom metal case (up to TSFC24) with foam inserts for secure transport and storage.

The TAG Split Frame Clamshell, crafted from high-grade aluminum and treated steel, is essential for pipe cutting, bevelling, J-prepping, and machining tasks in on-site industrial environments, making it a highly adaptable and reliable pipe bevelling machine.

OPERATING MANUAL

Related Products